An Overloaded Diesel Particulate Filter is Expensive.

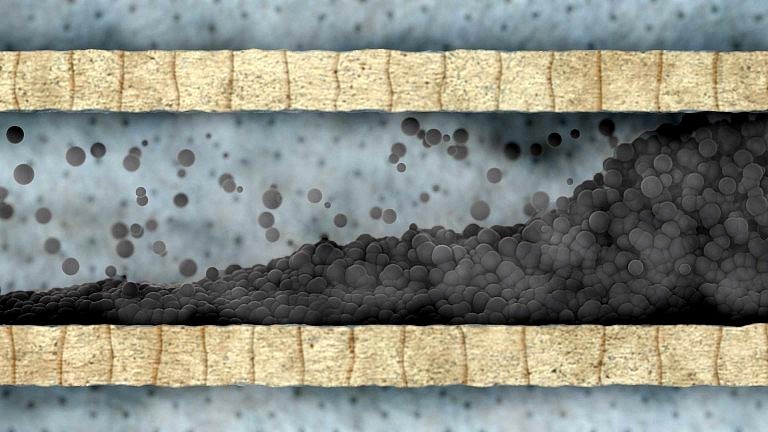

The diesel particle filter (DPF), also known as soot particle filter or simply particle filter, has the task of filtering health-endangering particles out of the exhaust system. In addition, the particle filter burns the soot that has collected on the filter pockets. This soot burn-off depends on the respective operating conditions, the different driving cycles and the individual engine exhaust concept of the automobile manufacturer. In order to comply with emissions standards, the diesel particulate filter (DPF) - as the name suggests - is used on vehicles with a diesel engine.

The Cost-Effective Alternative to Replacing the Particulate Filter

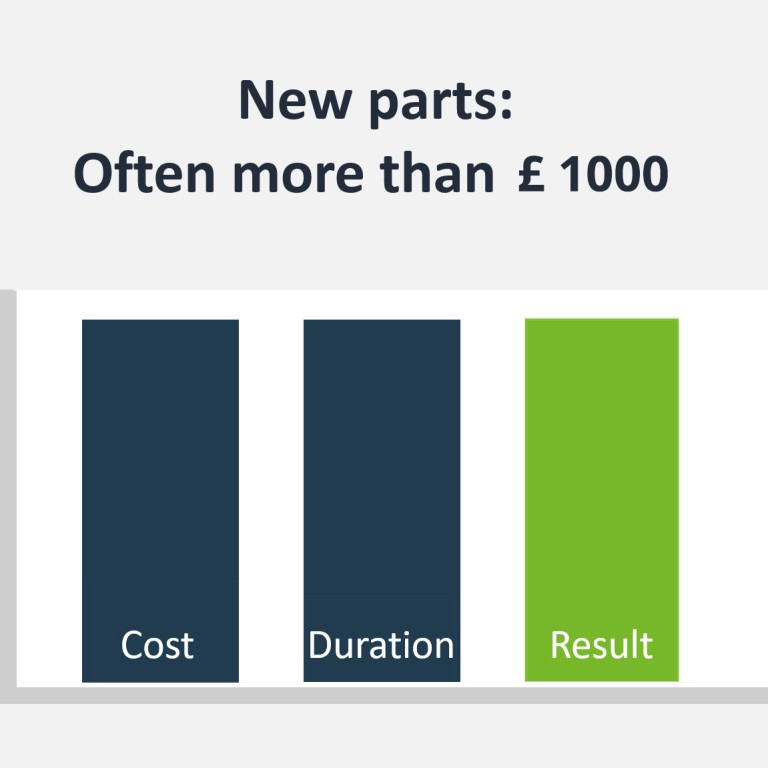

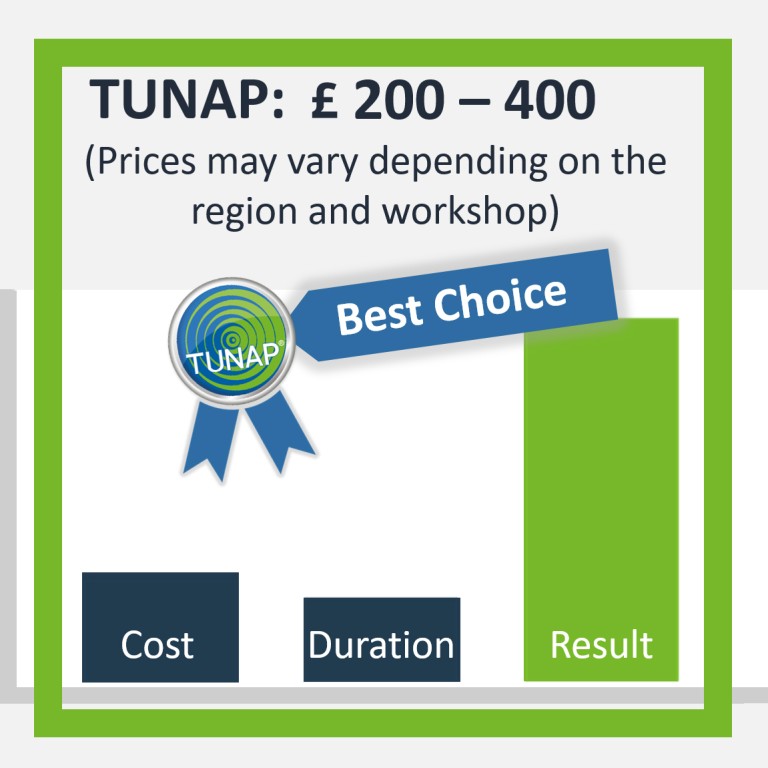

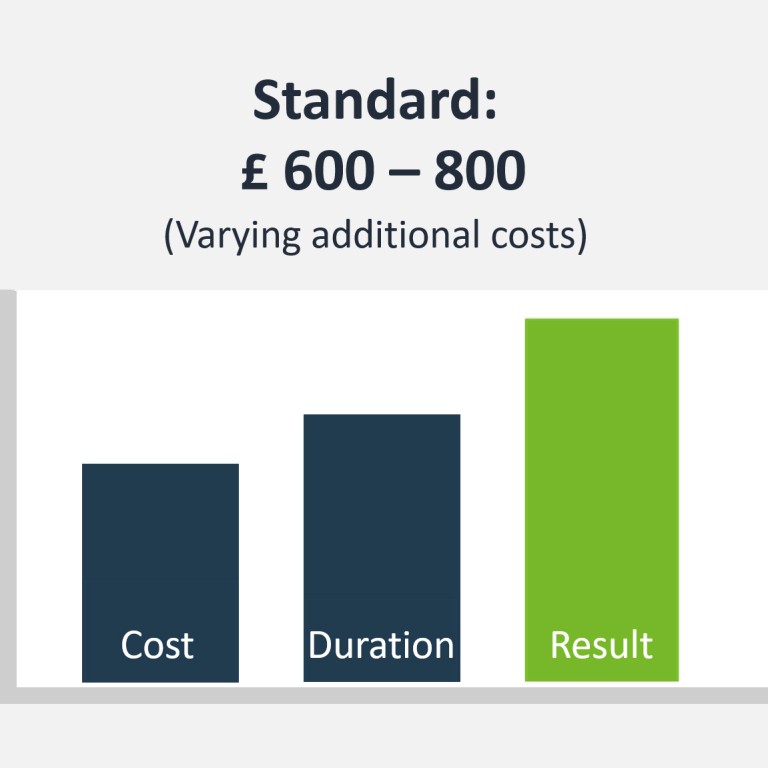

If the particle filter is clogged with particles, however, it can quickly become very expensive: Customers have to dig deep into their pockets to replace a diesel particulate filter.. A new diesel particulate filter (DPF) costs between £1,000 and £6,000. In addition, a longer workshop visit of the car and a chargeable replacement vehicle must be planned. In contrast, cleaning the particle filter with the TUNAP solution is an extremely cost-effective and inexpensive alternative.

The TUNAP Solution: Cleaning Instead of Replacement

- Makes for customer satisfaction

- DPF is back at work quickly

- DPF cleaning does not require expensive removal

- Our solution is technically approved by leading makers

- Enormous cost savings

- Preventive measures that keep your clients mobile long term

- Proven over a quarter of a million times

Symptoms and problems

An increasing loading of the particle filter without regular regeneration leads to a blockage of the component. The consequences are:

- Loss of engine power

- Increasing fuel consumption

- Suboptimal throttle response

Application and effect

Instead of replacing it, the particle filter is cleaned when it is installed:

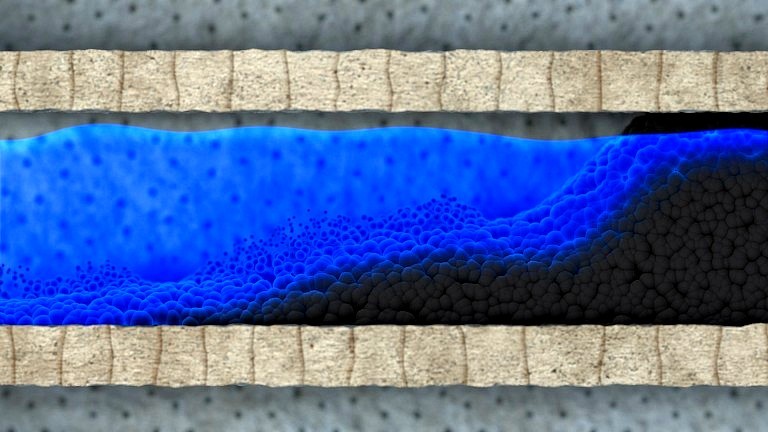

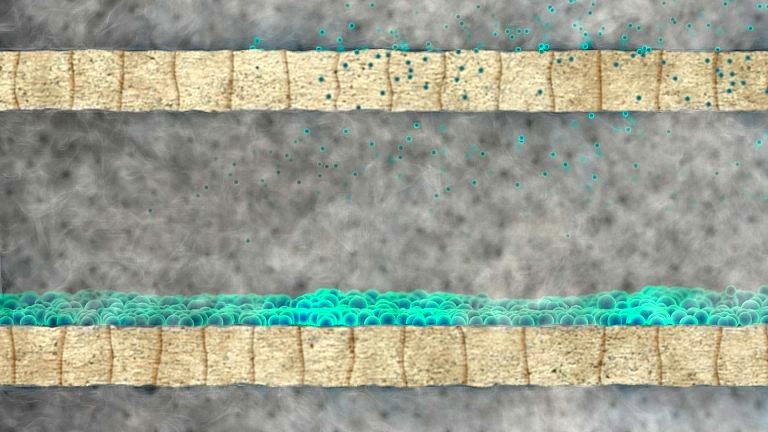

- The cleaning fluid dissolves the deposits on the component and

- the neutralising solution ensures the complete removal of particles that are not transported away.

Result of the DPF cleaning

The use of cleaning fluid and rinsing solution enables

- a subsequent regeneration in which the soot deposits are burned to CO₂.

- There is no additional burden on the environment.

- The particle filter is fully functional again after cleaning.

Diesel particle filter cleaning fluid and flushing solution

microflex® 931 and 932

The cleaning set for diesel particulate filters (DPF) consists of a nonflammable and metal-free cleaning liquid and a rinsing solution. The non-flammable and metal-free cleaner dissolves particles such as carbon and ash deposits in diesel particulate filters (DPF). In conjunction with the neutral purging solution, the exhaust gas pressure ensures smooth removal of the soot and ash particles from the exhaust system or from the particle filter.

- Cleaning without disassembling the particulate filter

- Nonflammable

- Neutral ash- and metal-free formulation

- Residue-free evaporation

- Material compatibility

Pressure cup gun for cleaning particle filters

For optimal use of the diesel particulate filter cleaner, we have developed a special pressure cup gun with a HD-PE pressure cup.

There are different probes to choose from for the different component shapes and the different access options to the particle filters.

Innovative Particle Filter Cleaning from TUNAP

You can compare the different procedures:

- The exchange or purchase of a new particle filter,

- the removal of the particle filter with shipping for cleaning and

- the patented TUNAP particle filter cleaning when installed.

Diesel Particulate Filter Cleaning (DPF) in our Video

Direct Comparison of Cleaning the Diesel Particulate Filter (DPF)

TUNAP Services

Questions and Answers about Particulate Filter Cleaning

There are various reasons for blocked particulate filters. The most common are:

- Sooty/dirty injectors

- Dirty EGR system

- Fluctuating fuel quality

- Unfavourable driving profile: The vehicle is not driven on long journeys, with the result that the filter is not regenerated

- Cleaning the particulate filter while it remains in place (TUNAP diesel particulate filter cleaning)

- Removing the particulate filter to clean it

Particulate filters cleaned with the TUNAP system are comparable to new particulate filters. To ensure that the particulate filter functions for a long time, you must find and eliminate the reasons for the blockage, otherwise the filter could clog up again.

TUNAP particulate filter cleaning fluid is not flammable.

The VERT® Association verifies and recommends the effectiveness of the TUNAP particulate filter cleaning process.

Generally, particulate filters only have to be replaced if components are actually defective. When filters are blocked or sooty, it is sufficient to clean the filter.

Basically, SCR and NSC catalysts have nothing to do with particulate filter cleaning. These components are installed in newer vehicles (mainly EURO 6) to reduce nitrogen oxide (NOx) emissions. When the particulate filter is being cleaned, they only come into contact with the TUNAP cleaning fluid when it is being discharged.

To prevent renewed blockage of the particulate filter, you must eliminate the causes of the blockage:

- microflex 989 Injector Direct Cleaner: Frees injectors of fuel-related sediment such as deposits of carbon or resin.

- microflex 925/926 EGR System Cleaner: The innovative XFoam technology dissolves stubborn contamination in the vehicle intake and exhaust systems.

- The quality of the fuel varies from garage to garage. Regular addition of microflex 984 Injector Direct Protection can prevent contamination in the injectors.

- Drive longer distances (preferably on motorways) with more strain on the engine. Regular use of the micrologic 184 Particulate Filter System Ingredient can also prevent blocked particulate filters, even with unfavourable driving profiles.

During TUNAP particulate filter cleaning, the soot deposits in the particulate filter are dissolved and are then burned to form CO₂ during normal regeneration of the filter. There are no additional impacts for the environment. We also prevent the environmental damage that arises from the manufacture of a new particulate filter. For example, through raw material extraction and the enormous energy consumption during the manufacture of a new part.